¡¡¡¡

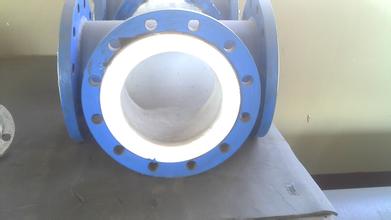

Rubber lining in industrial applications there are a lot of you in the industry has a pivotal position. But the factors that affect the performance of rubber lining and had a lot of life, generally have the following points.

Rubber lining in industrial applications there are a lot of you in the industry has a pivotal position. But the factors that affect the performance of rubber lining and had a lot of life, generally have the following points.1, rubber lining performance

Adhesive-lined rubber liner according to their use of the environment may be, if the selected physical and chemical properties of rubber and does not match the environment will result in greatly reduced service life loss and other serious consequences rubber layer.

2, rubber and adhesive strength steel

The non-rubber adhesive mortar production enterprises is not strong, backing layer will cause uneven stress can be a good decomposition, leading to local uneven force, resulting in a partial fast rubber lined pipe corrosion.

3, mining conditions

Use of premises, corrosive, temperature and intensity of use, etc. will affect the life of rubber lined pipes, rubber lined pipe and hence, in the beginning to make a rational choice analysis.

To achieve the best performance rubber lined pipe must first learn to choose, according to the actual working conditions, to choose the right materials and the rational design of rubber lining to adapt to the needs of the work, but also in the installation to be based on proper operation, If you do not know what we could also be consulted.

- Previous£ºNO

- Next£ºStudy on heavy duty coating sy 2016/3/28